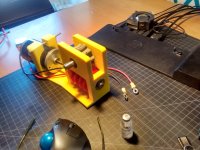

3D-Printed Gearbox

Andrew's Project Portfolio

This was my final project for my machine design class, a gearbox with an 8.6 gear ratio deisgned in Autodesk's Inventor 2016 and additively manufactured on a Stratasys Fortus 380mc.

The gearbox is straightforward, I added flanged ball bearings, turned two stainless steel shafts on the lathe and held everything in the correct position with E-clips snapped into grooves I cut into the shafts.

The more interesting aspect was learning how to setup a production-scale dual-extruder 3D printer from scratch:

- Because the part has long thick parts to it, any height variation on the substrate plate would compound its way through the whole part. As such, a lot of effort went into substrate setup.

- The part is thick in some places; as such preheating the oven to negate internal stresses is key to a high-fidelity print.

- The software driving the Fortus has its own algorithms to print most efficiently, but I learned in my own research that the choices made sometimes go against structural strength or rigidity.

Overall, this project taught me a lot more than how to choose materials and design with consideration of safety factors and such, I just as importantly learned that I needed to look past the default options provided in both design & manufacturing. Perhaps one could easily extend that lesson into life generally.